How secure is the UK’s food supply?

Many of us will have spent the last month buying, preparing, cooking, eating and talking about food. With New Year traditionally viewed as a time to shed indulgences after festive excesses, and retailers are posting their performance over the Christmas period, food security might be a long way from our thoughts right now.

But an independent report published last month gives valuable insights into the status of the UK’s food security – and how worried we should be.

Taking stock – every three years

The United Kingdom Food Security Report (UKFSR) examines factors from global availability, to domestic production and supply chain resilience.

Mandated by the Agriculture Act 2020, this independent, triennial report is designed to inform policy-makers and stakeholders about the current state and future outlook of the UK’s food security.

The report considers five key themes:

- Global food availability

- UK food supply sources

- Food supply chain resilience

- Food security at household level

- Food safety and consumer confidence

What do we really mean by “food security?”

The UKFSR uses the 1996 World Food Summit which defines food security as:

“When all people, at all times, have physical and economic access to sufficient safe and nutritious food that meets their dietary needs and food preferences for an active and healthy life.”

We can debate the merits (or otherwise) of this interpretation and talk about calorie security and poor nutrition in all its forms, (both under- and over-nourished diets), however several key – and uncomfortable – facts emerge from the analysis in the report.

Resilience amid volatility

The interconnectedness of global food systems is both an opportunity and a vulnerability.

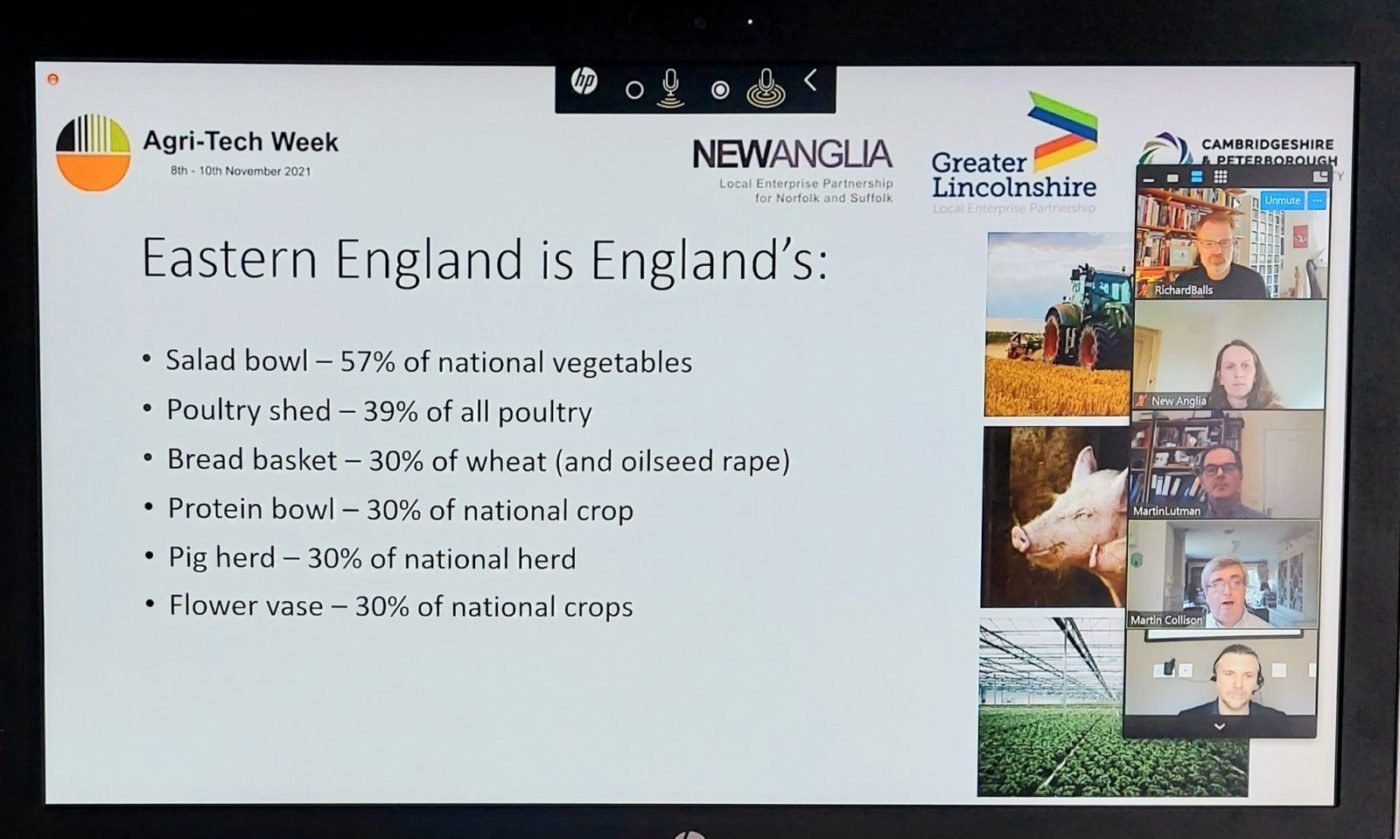

The UK relies heavily on imports (around 40% of our food), particularly for fresh produce. While domestic fruit production has doubled since 2004 (now equating to 16% of demand), the UK remains far from self-sufficient.

This leaves us exposed to volatile factors like harvest fluctuations (the UK’s wheat harvest fell 22% in 2024 compared with 2023) and geopolitical disruptions.

As of December 2024, 17 countries have implemented 22 export bans, and 8 introduced export-limiting measures.

Yet the report highlights some welcome resilience. UK supply chains, while stressed, have adapted, and domestic production in areas like soft fruit continues to grow.

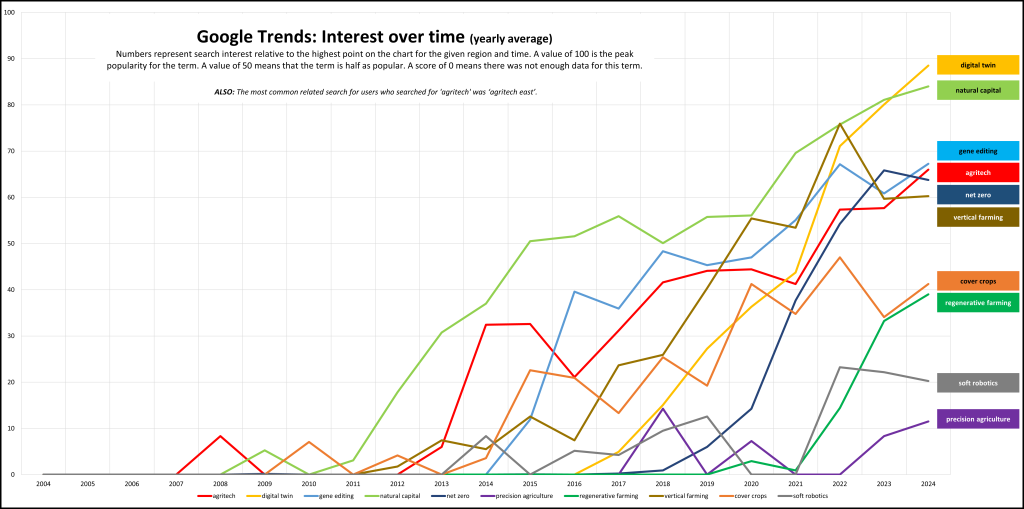

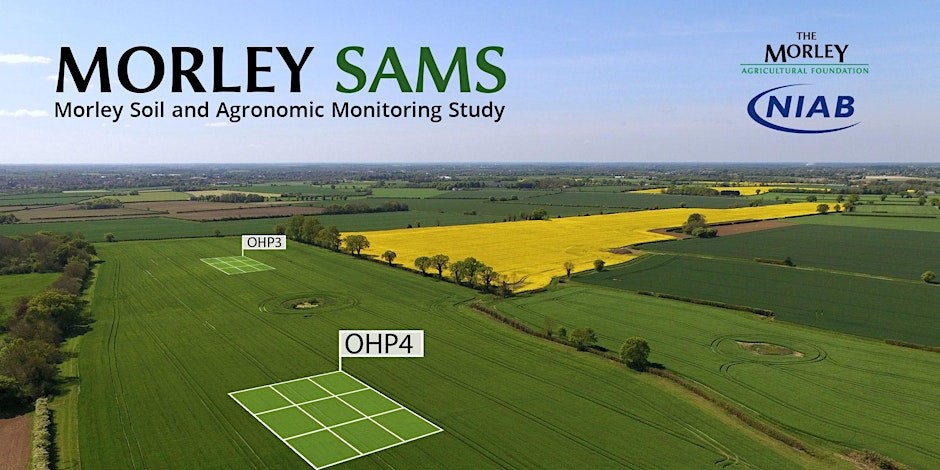

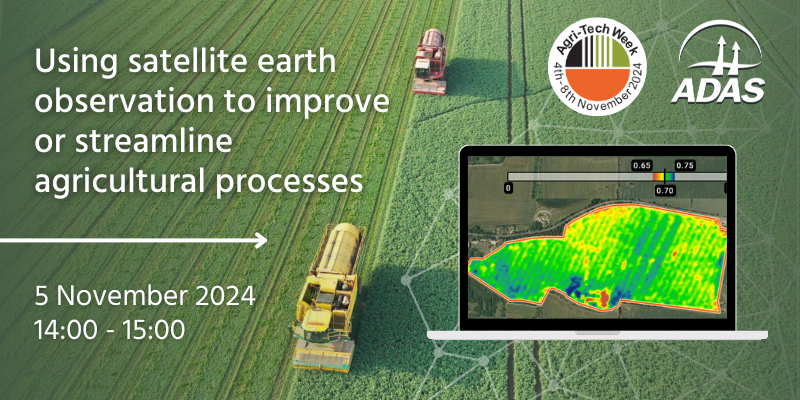

Moving forward, we can build greater resilience by exploring opportunities for enhanced domestic production. Such as through protected and controlled-environment farming (e.g. LettUs Grow and Innovation Agri-TechE Group), precision agriculture (such as the Omnia system developed by Hutchinsons), and innovations in crop diversity (including breeding work by Niab and Elsoms).

For imports that can’t be grown in the UK (e.g. bananas), supply chain diversification and adopting innovative trade policies will help to buffer disruptions. And we may explore shifting consumer preferences towards more local, sustainable alternatives (e.g. Morrow coffee).

Protecting – and enhancing – natural capital

One of the report’s more encouraging findings is that the decline in natural capital – the soil, water, and ecosystems that sustain our food systems – appears to have levelled off. This is likely due to the adoption of sustainable farming practices in recent years, such as better land management, reduced pesticide use, and increased adoption of regenerative agriculture.

However, progress remains fragile with natural capital still at a very low level compared to its historic state. The challenge now is ensuring this plateau becomes a sustained recovery – a baseline to enhance, not an end point.

Addressing inequalities in food security

Perhaps the most striking fact from the report is the decline – and unequal distribution – of food security in the past five years. Depending on income, between 13% and 42% of UK households fail to meet Government dietary recommendations.

Poor access to nutritious, affordable food highlights the need for systemic changes – and innovation can play its part, for example by helping to reduce waste and inefficiencies in the supply chain to lower costs.

What’s next?

This report sits at the heart of our personal and national health and wealth, not to mention informing decisions about the land-use framework and the wider agri-food ecosystem.

As we move into 2025, there is an opportunity – and responsibility – to drive innovation and collaboration across the food system. This report is a call to action for all of us working to build a more resilient, sustainable, and equitable food future – we disregard its contents at our peril!

Agri-TechE

Agri-TechE

Innovation Agritech Group

Innovation Agritech Group

University of Essex

University of Essex

Albotherm

Albotherm

Royal Norfolk Agricultural Association

Royal Norfolk Agricultural Association

LettUs Grow Ltd.

LettUs Grow Ltd.

Agri-TechE

Agri-TechE

Gardin Ltd

Gardin Ltd