GrowUp Farms aims to change food systems

Kate Hofman is the CEO of GrowUp Farms. In 2014, the company established Unit 84, the UK’s first commercial-scale vertical farm. Sales from the prototype Unit 84 were made through local supply chains and restaurants across London – with a focus on social and environmental sustainability.

Having been in the business of commercial controlled environment salad production since 2012, starting off with shipping container aquaponics before scaling up, Kate is in an excellent position to comment on the challenges of breaking into the UK leafy green supply chain using a vertical farm.

Q. Are GrowUp technology developers or growers?

Our focus is very much as a salad grower that grows a fantastic product that everyone will want to buy. To bring down the cost of sustainable food, means doing it at a big enough scale to gain the economies of production that are needed to be able to sell at everyday prices.Our long-term strategy is to continue to build toward this model of producing affordable product, and to continue to be a grower rather than a technologist.

From a tech development point of view, indoor farming is still at a relatively early stage, and any industry at this stage will see ideas and concepts start in academia or start-ups, into early-stage development, later-stage development, and then into commercialisation from there. That’s reflected in where the indoor farming market is at the moment – a growing number of projects, technologies, business and products at different stages of development, and operating at different stages of the supply chain.

Q. What did you learn from your vertical farm: Unit 84?

Unit 84 was our commercial prototype, and was the largest in the UK when we built it – and that ran until the end of 2017. We had a local supply chain – our farm was in East London; we used an electric van to do all our local deliveries and worked with a wholesaler in Covent Garden market. We sold to local restaurants and various independent stores.

We have pivoted away from aquaponics, and now focus on controlled environment hydroponics; looking at how to optimise large scale production to bring down costs and reduce impacts.

Because of the scale we are now looking at, we are focussed on a wholesale model, so although we are less likely to work directly with individual restaurants and retailers as we did before, having conversations directly with consumers through smaller channels will always be important. It helps people understand where food comes from and how it’s made, and they can make better food decisions for themselves if they understand more about sustainability.

It is hard to break into traditional salad supply chains as the conventional industry is very consolidated and very commoditised.

We are a member of the leafy salad association, the AHDB’s salad wing, and because our ambition is to make what we do part of mainstream food production in the UK, we see the value in opening dialogues with all sectors of the industry in terms of research and best practise – there are opportunities for collaboration around things like sustainability and food safety.

And there is some overlap – I know several projects where conventional growers have looked into applying controlled environment technology to what they’re doing, but we are positioning ourselves as an alternative supplier to retailers.

Q. What does the future look like for vertical farming?

It will be really interesting to see how the food service world recovers after lockdown – the rough numbers are that supermarket trade was up at least 11% in the last year – so retail still looks like a really good direction to go in. If we want to have an impact on the food system in the UK and change it for the better, we’re committed to partnering with those big retailers to help them deliver on their sustainability and values-driven goals.

There are lots of exciting technological developments occurring, and I see that as a very positive thing. I like the idea of the UK becoming a centre of excellence for CEA production in the same way as we are for other agricultural innovation – it’s not just about the technology it’s about growing world class quality food and maintaining that agricultural heritage as a country known for its delicious produce.

More information about GrowUp Farms.

Agri-TechE

Agri-TechE

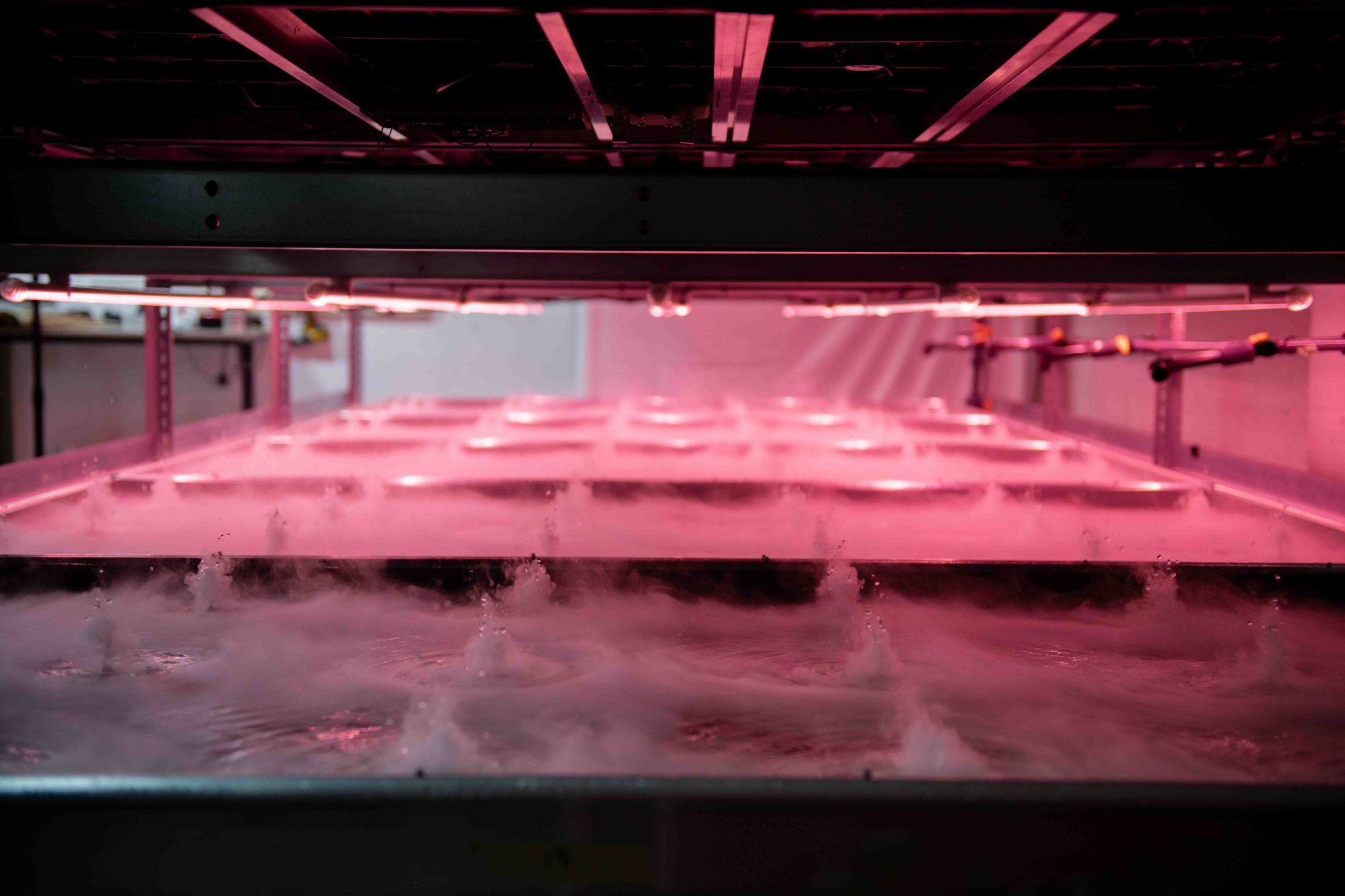

monitoring and control of the growing environment; ensuring optimal plant productivity and yield.

monitoring and control of the growing environment; ensuring optimal plant productivity and yield.

Agri-TechE

Agri-TechE