Is there a business case for widescale commercial vertical farming in the UK or will it remain a niche opportunity for high-end restaurants and retail? This is the challenge to be discussed by early adopters at the Agri-TechE conference ‘Innovating for Controlled Environment Agriculture’ 19 March. Advances in logistics and the falling cost of LED lighting may enable year-round growing of undercover produce in the UK, but will energy costs and technical issues delay scale-up and integration within the food supply chain?

Potential to be commercially viable

“We do think there is the potential for indoor farming to be commercially viable and there are some immediate gains for growing crops such as leafy salads in high hygiene environments,” comments Lindsay Hargreaves, MD of Frederick Hiam, a farming and fresh produce business with farms in Suffolk and Cambridgeshire. “Growing indoors provides greater control of quality and quantity and fewer inputs of plant protection products.

“There is also the matter of growing crops closer to the point of consumption. Being able to grow more exotic crops in East Anglia close to distribution centres would reduce the food miles. Additionally, there are opportunities to grow crops for pharmaceuticals, cosmetics and vaccines within a controlled environment.”

There are many approaches to indoor cultivation, such as deep-water hydroponics, vertical soilless cultivation, and aeroponics, where exposed roots are sprayed with nutrients. All of these methods are to be discussed at the conference along with advances in monitoring and robotics.

However, despite the news that Sterling Suffolk, one of the UK’s most technically-advanced glasshouses, is set to produce millions of tomatoes starting in February 2019, the cost (£30M) and the technical challenges mean there are few commercial installations in the UK.

Also, it is proving difficult to demonstrate to retailers that controlled environment agriculture (CEA) can bring tangible benefits to their supply chain.

Aquaponics provides fish with a side salad

Kate Hofman, co-founder of GrowUp Farms, which from 2015 to 2017 operated ‘Unit 84’, a commercial-scale aquaponic urban farm inside an industrial warehouse. The 8,200 square feet of growing space could produce enough for 200,000 salad bags and 4,000kg of fish each year. It sold directly into restaurants, through a New Covent Garden distributor and also through bricks and mortar supermarkets and Farmdrop, the online supermarket.

Kate comments: “A key learning over the last six years is that we can’t just focus on technology – we have to partner along the supply chain to create a business model that ultimately delivers commercial success for growers and retailers.

“One of the major challenges for CEA is to optimise operations to bring down the cost of production to match existing imported products. Our prototype urban farm showed that it was possible to use CEA commercially, and we were able to demonstrate the demand for the produce we could grow. This ranged from specialist micro-greens and cut herbs through to mixed baby leaf salad.

“We are now working on scaling up our business. This will involve relocating, so that our production is co-located with a renewable energy plant and working in partnership with more traditional farming businesses to integrate their experience and expertise.”

There are also technology challenges to be addressed when trying to meet the highly variable consumer demand for high quality, fresh produce.

Year around UK production?

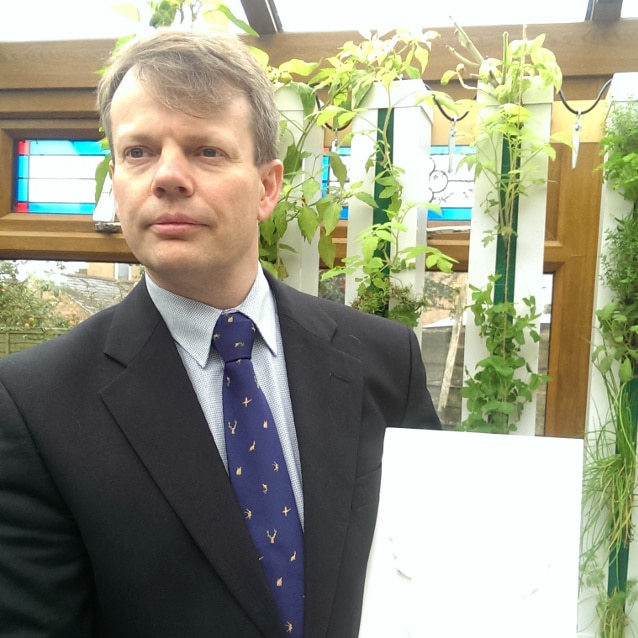

G’s Fresh supply baby leaf crops all year round, with much of the winter supply grown in Spain and Italy to ensure security of delivery. In summertime it produces a huge amount of outdoor salad crop, particularly lettuces and celery in the UK. Ben Barnes is investigating how controlled environment agriculture can increase the long-term viability and profitability of both of those parts of the business.

The organisation has a large standard greenhouse facility that is used to propagate seedlings for planting out into the field. It is running two projects: Smart Prop, which is looking at increasing the efficiency of the propagation facility to improve growth and make stronger plants so they transplant better back into the field. And Winter Grow, a pre-commercial trial, to see if it is feasible to produce baby leaf crops during the winter at an affordable price point.

Ben explains: “I’m going to be talking at the Agri-TechE event about the commercial journey, in terms of the go and no-go decision-making process and what the key things are that we need to learn in order to be able to make those kind of investment decisions.

“One element of this is the development of ‘lighting recipes’ to enhance plant growth characteristics. We’ve got multi-spectrum LED lights, so we can turn up the different amounts of red, blue, green and white, and even far red light. These are fairly expensive, so once we have worked out what works best we can buy fixed spectrum lights, which are a tenth of the cost.

“You think LEDs are very efficient, but they still generate a heck of a lot of heat when you’ve got them turned up to full. It is more about keeping the space cool, and the plants obviously are transpirating so we’ve got dehumidifiers in there sucking the moisture out of the air.

“One of the biggest problems with the vertical farming concept is this interaction between moisture and temperature. You’ve got the two factors constantly fighting against each other and that ends up sucking up huge amounts of energy if you’re not careful.”

How will it integrate with the value chain?

Dr Belinda Clarke is director of Agri-Tech, an independent membership organisation that is facilitating the growth of the agri-tech sector, comments that the commercial challenges need addressing along with the technical and agronomic aspects: “The promise of CEA is sustainable, intensive production but achieving that may require a different type of value chain.

“It could be that supermarkets of the future allow you to pick your own fruit and baby leaf instore, or we may see large-scale distribution of veg boxes, with produce grown indoors in optimum conditions or perhaps traditional growers would have more flexibility to grow a greater range of produce all year around with less waste.

“These ideas all have potential but also require significant capital investment and creative solutions for energy management. These are some of the themes we will discuss in the conference.”

‘Bringing the outside In – Innovating for Controlled Environment Agriculture’ taking place on 19 March from 10.00 – 16.00 at Rothamsted Research, Harpenden. It will look at the different growing systems, emerging technologies, the challenges of implementing a system and the logistics involved with integrating a controlled environment agriculture into the food value chain

Agri-TechE

Agri-TechE

Agri-TechE

Agri-TechE

G’s Fresh produces lettuce and other salad crops to meet the highly variable consumer demand for high quality, fresh produce. Ben Barnes is investigating how controlled environment agriculture can support the business.

G’s Fresh produces lettuce and other salad crops to meet the highly variable consumer demand for high quality, fresh produce. Ben Barnes is investigating how controlled environment agriculture can support the business. “Another option would be to take out heat and put it into the greenhouse, which would be a cost-saving. “Actually one of the biggest problems with the vertical farming concept is this interaction between moisture and temperature. You’ve got the two factors constantly fighting against each other and that ends up sucking huge amounts of energy if you’re not careful.”

“Another option would be to take out heat and put it into the greenhouse, which would be a cost-saving. “Actually one of the biggest problems with the vertical farming concept is this interaction between moisture and temperature. You’ve got the two factors constantly fighting against each other and that ends up sucking huge amounts of energy if you’re not careful.”

For centuries farmers have walked the fields to assess the rate of emergence of recently sowed crops, signs of disease and water stress. Now many are using drones to visualise the whole field and using special cameras to assess the rate of growth and provide early detection of pests or nutrient deficiency.

For centuries farmers have walked the fields to assess the rate of emergence of recently sowed crops, signs of disease and water stress. Now many are using drones to visualise the whole field and using special cameras to assess the rate of growth and provide early detection of pests or nutrient deficiency.

There is a big market opportunity for controlled environment agriculture (CEA) according to Rhydian Beynon-Davies, Head of Novel Growing Systems at Stockbridge Technology Centre (STC). He comments: “The world will need sustainable solutions to an increasing extent in the future and we should be the ones to supply those solutions.

There is a big market opportunity for controlled environment agriculture (CEA) according to Rhydian Beynon-Davies, Head of Novel Growing Systems at Stockbridge Technology Centre (STC). He comments: “The world will need sustainable solutions to an increasing extent in the future and we should be the ones to supply those solutions. Rhydian concludes: “Going forward I think we will see systems which are sub-divided for production of individual varieties, rather than the cavernous spaces growing multiple crops that are common in most current commercial CEA systems.

Rhydian concludes: “Going forward I think we will see systems which are sub-divided for production of individual varieties, rather than the cavernous spaces growing multiple crops that are common in most current commercial CEA systems.

“The big challenge of Controlled Environment Production (CEP) is to demonstrate to retailers that it can bring tangible benefits to their supply chain and their customers,” comments Kate Hofman, co-founder of GrowUp Farms. She is speaking at the Agri-TechE conference on controlled environment production taking place at Rothamsted Research on 19 March.

“The big challenge of Controlled Environment Production (CEP) is to demonstrate to retailers that it can bring tangible benefits to their supply chain and their customers,” comments Kate Hofman, co-founder of GrowUp Farms. She is speaking at the Agri-TechE conference on controlled environment production taking place at Rothamsted Research on 19 March. “Our prototype urban farm showed that it was possible to use CEP commercially, and we were able to demonstrate the demand for the produce we could grow. This ranged from specialist micro-greens and cut herbs through to mixed baby leaf salad. We sold directly into restaurants, through a New Covent Garden distributor and also through bricks and mortar supermarkets and Farmdrop, the online supermarket.

“Our prototype urban farm showed that it was possible to use CEP commercially, and we were able to demonstrate the demand for the produce we could grow. This ranged from specialist micro-greens and cut herbs through to mixed baby leaf salad. We sold directly into restaurants, through a New Covent Garden distributor and also through bricks and mortar supermarkets and Farmdrop, the online supermarket.

“We do think there is the potential for indoor farming to be commercially viable and there are some immediate gains for growing crops such as leafy salads in high hygiene environments,” comments Lindsay Hargreaves, MD of Frederick Hiam, a Suffolk-based fresh produce business. He is chairing the Agri-TechE conference on controlled environment cultivation taking place at Rothamsted Research on 19 March.

“We do think there is the potential for indoor farming to be commercially viable and there are some immediate gains for growing crops such as leafy salads in high hygiene environments,” comments Lindsay Hargreaves, MD of Frederick Hiam, a Suffolk-based fresh produce business. He is chairing the Agri-TechE conference on controlled environment cultivation taking place at Rothamsted Research on 19 March. “There is also seasonality. Thirty years ago the berry market in the UK had a short growing season; now strawberries are a long season as well as high value crop, not just a luxury available for a few weeks. Bringing new crops indoors could open up big markets for UK growers.”

“There is also seasonality. Thirty years ago the berry market in the UK had a short growing season; now strawberries are a long season as well as high value crop, not just a luxury available for a few weeks. Bringing new crops indoors could open up big markets for UK growers.” “However, it is coming. I am sure a few years ago we wouldn’t have imagined that we would have a computer in our pockets so powerful that you could talk face-to-face with someone across the world! You need to have vision.”

“However, it is coming. I am sure a few years ago we wouldn’t have imagined that we would have a computer in our pockets so powerful that you could talk face-to-face with someone across the world! You need to have vision.”

Tomatoes, strawberries and other crops grown undercover are a rich source of active plant ingredients such as lycopene, anticyanins and isoflavones that are used in the cosmetic and health industries. A workshop hosted by Niab will be reviewing the options for growers in the emerging bioeconomy on Friday 10th November during Agri-Tech’s Agri-TechE Week 2017.

Tomatoes, strawberries and other crops grown undercover are a rich source of active plant ingredients such as lycopene, anticyanins and isoflavones that are used in the cosmetic and health industries. A workshop hosted by Niab will be reviewing the options for growers in the emerging bioeconomy on Friday 10th November during Agri-Tech’s Agri-TechE Week 2017.