LettUs Grow with sound – ultrasonic aeroponics increase growth rate

By growing plants with ultrasonics and water instead of soil, LettUs Grow has doubled growth rates with its ultrasonic aeroponics when compared to conventional hydroponic systems.

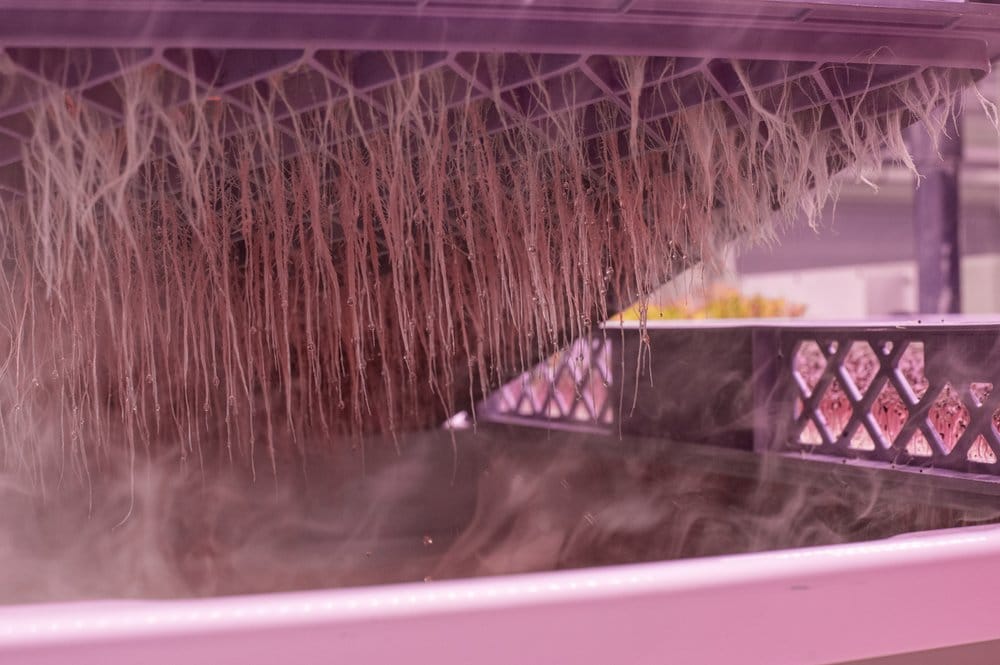

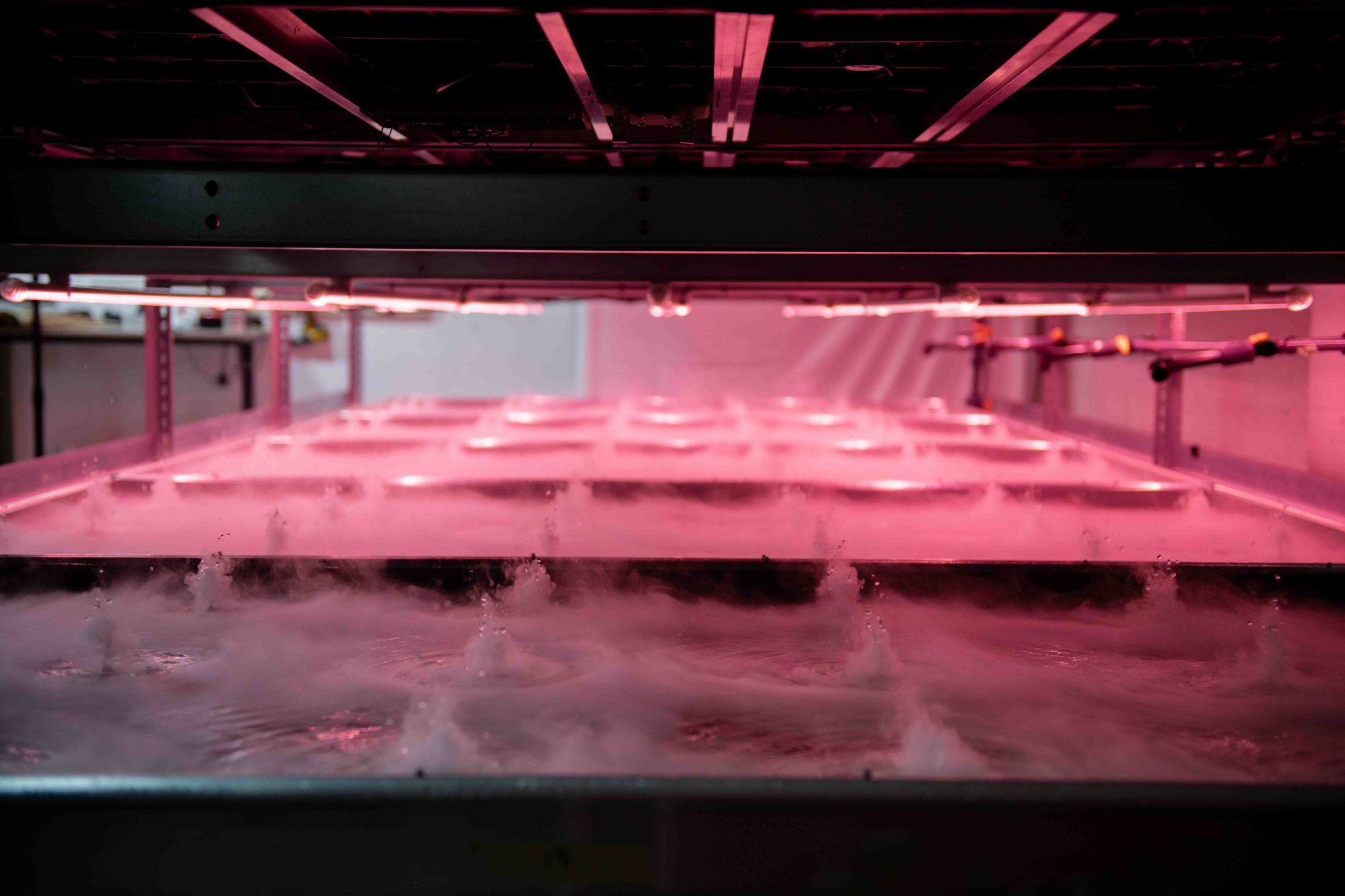

Ultrasonic technology is harnessed to create high-frequency sound waves that shake water until it disperses into lots of tiny droplets, like a mist. This mist can be distributed and controlled to provide the exact amount of water and nutrients to plant roots depending on their needs and stage of growth.

Irrigating plants with mist rather than liquid water is not new – the practice is called aeroponics. Instead of growing in soil, plant roots are suspended in air – this mimics the air pockets found in a healthy soil system, boosts access to oxygen, and results in much faster growth of the plant.

This growing method allows plant roots to grow healthier and faster than in hydroponics, which is the most common irrigation system used in greenhouses and vertical farms today. In-house trials at LettUs Grow have shown that this ultrasonic method also uses much less water.

Charlie Guy, co-founder & CEO of LettUs Grow says: “By harnessing our unique ultrasonic technology, we can offer growers the ability to grow consistent, healthy and high-quality produce with far less impact on our natural environment.”

Ultrasonic aeroponics

Aeroponics more commonly uses nozzles to generate mist. However, technical complexities and issues with maintenance have prevented aeroponics being successful in larger scale agricultural applications such as greenhouses. A key component of ultrasonic aeroponics is the use of an atomiser, the device which transforms liquid into mist. This removes the need for nozzles, therefore increasing the viability of using aeroponics in much larger, commercial growing spaces, where its impact is maximized:

Lilly Manzoni, Head of Research & Development at LettUs Grow. “This is the first atomiser that has been specifically designed for aeroponic agriculture. This means we’ve developed them to be durable and operationally efficient, with the environment and the grower in mind.”

As well as being designed to benefit commercial agriculture, aeroponics is also ideal for research applications. This is because the nature of the mist, rather than water, and access to the roots, means it’s possible to have a very precise high-level of control over plants in the system.

“This means that there are so many different potential applications of harnessing this technology, such as in forestry, biomass production and other projects that could improve and protect natural ecosystems.”

Agri-TechE

Agri-TechE

Agri-TechE

Agri-TechE

Delta Robots, which resemble spiders, are now widely used on assembly lines and have applications in agri-food where they have been shown to increase productivity. The robots typically have three or four lightweight, carbon-fibre arms that extend downwards from the main robot body. They are well suited to pick and place and packaging applications.

Delta Robots, which resemble spiders, are now widely used on assembly lines and have applications in agri-food where they have been shown to increase productivity. The robots typically have three or four lightweight, carbon-fibre arms that extend downwards from the main robot body. They are well suited to pick and place and packaging applications.

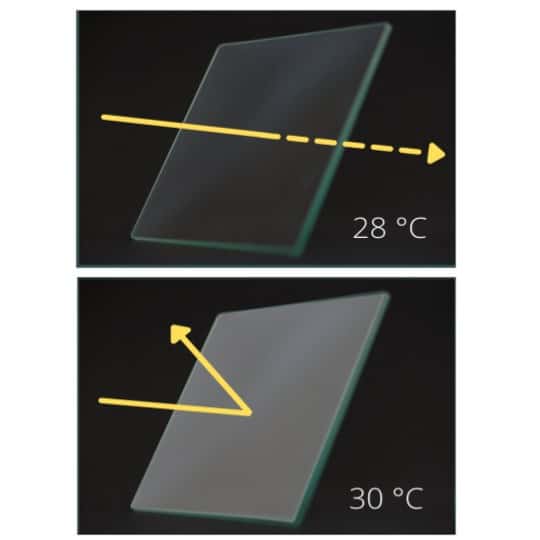

Yield, taste and time to harvest can all be impacted by light. So, increasing the rate of photosynthesis, the process by which plants convert sunlight to biomass, has the potential to improve agricultural productivity and the nutritional value of the crop. Technologies to extract greater value from available light and the feasibility of year around production of green vegetables are among the topics to be discussed at the Agri-TechE event ‘

Yield, taste and time to harvest can all be impacted by light. So, increasing the rate of photosynthesis, the process by which plants convert sunlight to biomass, has the potential to improve agricultural productivity and the nutritional value of the crop. Technologies to extract greater value from available light and the feasibility of year around production of green vegetables are among the topics to be discussed at the Agri-TechE event ‘

Lighting can also be used to reduce time to harvest, according to research by Jim Stevens of Vertical Future, an engineering firm that designs controlled environments for clients. Vertical Future recently announced a £21million fundraising round, which will be used to boost its development pipeline and widen the options of what can be grown.

Lighting can also be used to reduce time to harvest, according to research by Jim Stevens of Vertical Future, an engineering firm that designs controlled environments for clients. Vertical Future recently announced a £21million fundraising round, which will be used to boost its development pipeline and widen the options of what can be grown.