UK researchers use aeroponics to boost B12 in pea shoots

A team of UK researchers has harnessed aeroponic indoor farming to biofortify pea shoots with Vitamin B12, offering a sustainable and nutritious dietary solution in line with the Eat Lancet Planetary Health Diet and WWF Eat4Life recommendations.

Biofortification involves enhancing the nutritional content of crops, increasing the levels of specific vitamins or nutrients beyond the amount typically found in that plant. This approach offers substantial potential in addressing malnutrition, particularly in regions where access to nutrient-rich foods is limited.

Vitamin B12: A Nutritional Powerhouse

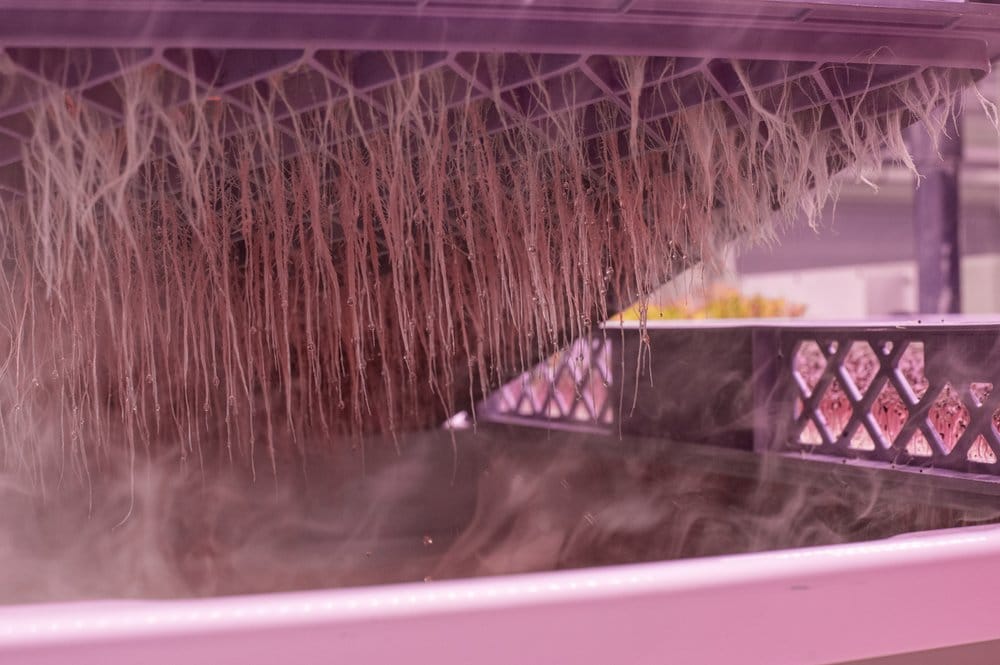

In a project funded by the Biotechnology and Biological Sciences Research Council (BBSRC), scientists from the John Innes Centre, LettUs Grow, and the Quadram Institute have targeted Vitamin B12 as a key nutrient for biofortification. By utilising LettUs Grow’s cutting-edge ultrasonic aeroponic technology, they have successfully grown B12-fortified pea shoots, providing the recommended daily dose in a single portion.

Traditionally, Vitamin B12 is primarily obtained from animal sources, and its deficiency can lead to severe and irreversible damage. As the global trend moves toward plant-based diets for both human and planetary health, biofortification offers a vital alternative source of this essential nutrient.

Prof. Martin Warren, Chief Scientific Officer at the Quadram Institute, emphasises: “This is a really exciting development in providing an adequate intake of Vitamin B12 to enhance overall health and well-being as B12 plays a crucial role in various bodily functions, including red blood cell formation, nerve function, and DNA synthesis.”

Unlocking Nutritional Potential

Biofortified crops integrated into common foods align with dietary habits, making it easier to adopt sustainable dietary changes. Unlike synthetic vitamin supplements, these crops offer a broader range of nutrients, including vitamins, minerals, antioxidants, and phytochemicals, supporting overall health.

Prof. Warren continues: “While Vitamin B12 supplements are available, some people may find it more convenient and natural to obtain essential nutrients directly from whole foods. Fortified plants hold the potential to provide a more integrated way to meet nutritional requirements.”

Sustainable Agriculture with LettUs Grow’s Indoor Farming

As the world seeks to transition to sustainable and eco-friendly diets rich in plant-based foods, biofortification presents a compelling solution. For instance, a standard salad bag grown through this method could contain as much B12 as two portions of beef, making it easier for individuals to adopt sustainable dietary changes.

However, achieving the sustainable growth of biofortified crops on a scale to feed the growing population remains a challenge.

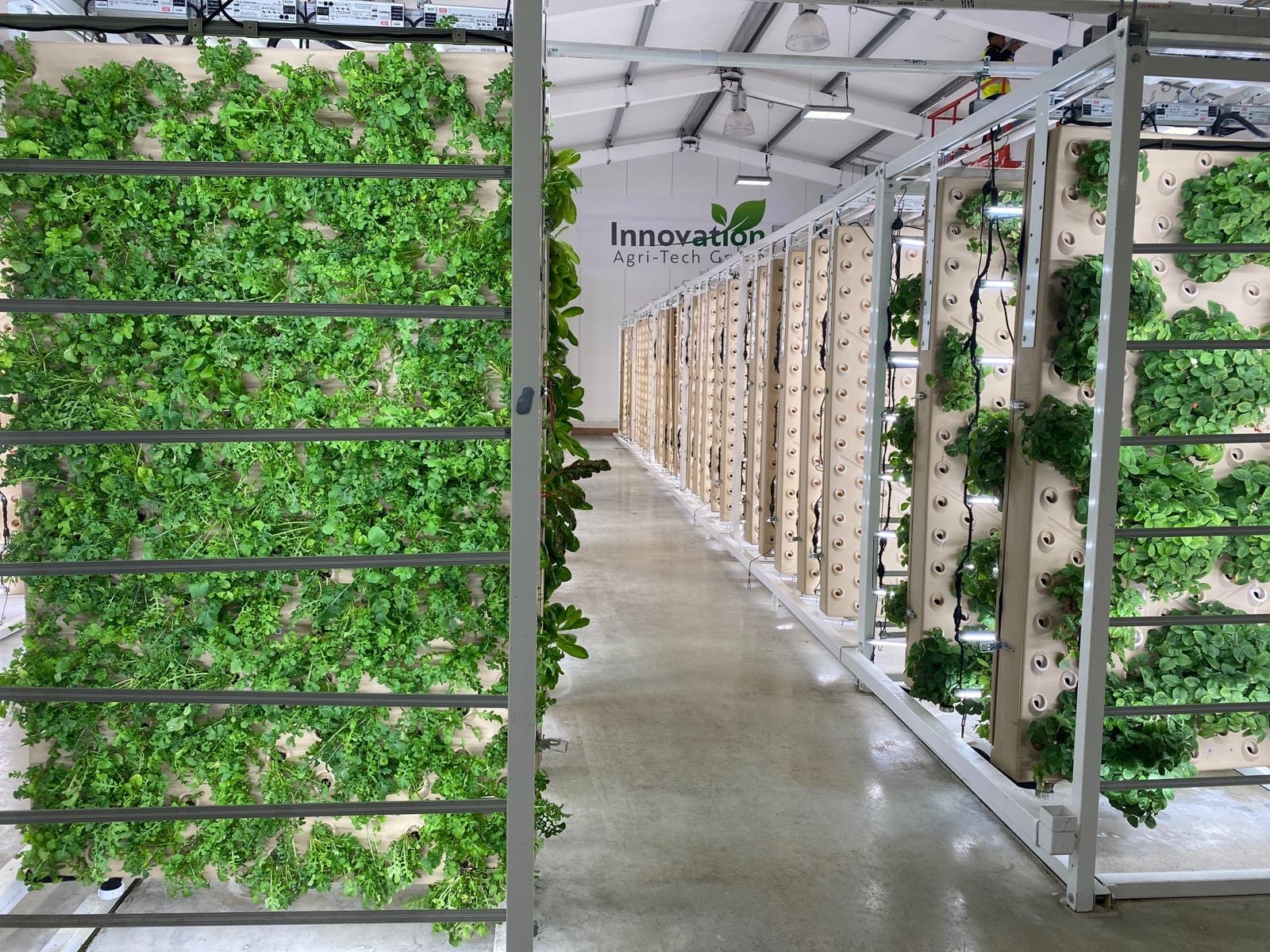

The scientists at John Innes Centre, Quadram Institute and LettUs Grow believe the answer lies in aeroponic indoor farming. The controlled environment ensures year-round growth, efficient resource use, and eliminates traditional farming risks like pests, diseases, and unpredictable weather.

Indoor farming, encompassing greenhouses and vertical farms, plays a vital role in biofortification. It creates the ideal growth environment for crops and, through aeroponics, allows precise nutrient delivery, to optimise crop nutritional profiles.

LettUs Grow’s distinctive aeroponic system operates with high-frequency sound waves (exceeding 20,000 Hz) to convert water into a fine mist, effectively delivering both water and nutrients to crops with unparalleled precision. This precision empowers the research team to fine-tune the nutritional profiles of the biofortified crops.

A Revolution in Nutrition

Lilly Manzoni, Head of Research and Development at LettUs Grow said: “Something that’s really exciting about this project in particular is that it is the first time the enhanced yield potential of aeroponics has been combined with the nutrition enhancement of B12 fortification in a way that can be scaled up to commercial volumes. This potential to scale the innovation is crucial for accessibility of the end product and getting it out at a level that could hopefully positively impact public health.”

Prof. Antony Dodd, Head of Cell and Developmental Biology at the John Innes Centre, states: “By combining expertise in plant sciences, human nutrition, and horticultural engineering, we are developing new approaches to address nutritional deficiencies at a relatively low cost.”

This project showcases the power of collaboration between academia and industry to drive positive change in people’s diets. Biofortification coupled with indoor farming has the potential to combat malnutrition, promote sustainable diets, and contribute to a healthier, nourished world.

Agri-TechE

Agri-TechE

Agri-TechE

Agri-TechE

promise of continuity and consistency of supply, reduced food miles and the need for fewer inputs.

promise of continuity and consistency of supply, reduced food miles and the need for fewer inputs.

Agri-TechE

Agri-TechE

Wageningen is an exemplar of the Quadruple Helix Model of innovation, which is where the university, industry, government and public interact within a knowledge economy.

Wageningen is an exemplar of the Quadruple Helix Model of innovation, which is where the university, industry, government and public interact within a knowledge economy.

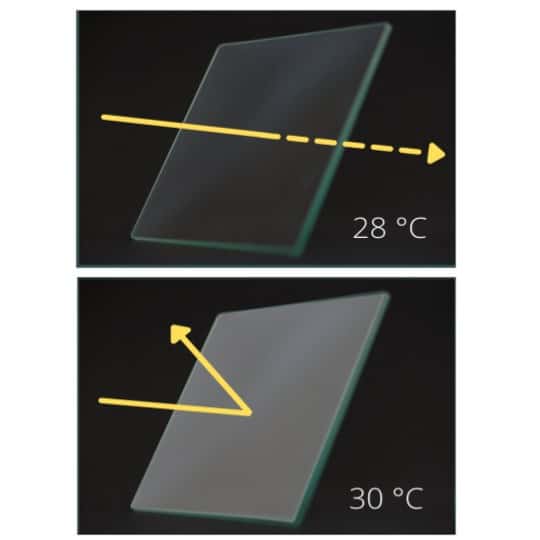

Supplementary light was found to increase tomato crop yield by up to 12.1%, a trial by Light Science Technologies (LST) and CHAP has found.

Supplementary light was found to increase tomato crop yield by up to 12.1%, a trial by Light Science Technologies (LST) and CHAP has found.  This provides benefits to food producers by offering more reliable trial conditions for their products, especially for biopesticides, with consequent benefits to the crop production sector in the form of increased product availability.

This provides benefits to food producers by offering more reliable trial conditions for their products, especially for biopesticides, with consequent benefits to the crop production sector in the form of increased product availability.