Livestock tech provides alerts that boost productivity

Livestock tech should be designed around the needs of the farmer, says Helen Reeve, a self-confessed cow geek and a lecturer at the Easton College, training and supporting apprentices. She says that it is vital that stock-keepers keep aware of emerging technologies, but she adds it is equally important that livestock tech improves productivity.

“Technology should complement, not replace, the skills of livestock farmers and breeders,” she says.

Helen, the owner of Waveney Dexter Beef, is talking in the Farmer Panel at REAP 2024 and urges farmers and students to apply for a bursary to attend the conference to hear about the latest developments in agri-tech. The bursary is generously provided by the Royal Norfolk Agricultural Association (RNAA) to reduce the cost of participation in this dynamic conference.

Helen has built her herd from nothing and here describes her journey.

Livestock farming – beef and dairy

I have always wanted to be a farmer, but it can be a lonely occupation. When I am visiting apprentices on the farm, I am often aware that I might be one of only a few people that they see regularly, so rural mental health is very important to me – as the hashtag says: #MindTheirHead.

I come from a long line of farmers but sadly there was nothing for me to inherit. So, I started out with a handful of Dexter cows and rented land and buildings along the Waveney Valley in Norfolk.

Dexter cattle are the smallest native breeds of cattle you can get in the UK, and they’re dual purpose, which means they can provide quantities of milk and quality beef.

I have about 60 cows, which I am breeding from. The cows calve on a regular basis every few months; the females are retained to build the herd and the males fattened for beef. The cattle are mostly grass-fed, either through grazing or through winter forage – hay and silage.

All beef cattle is reared to 30 months and then taken to the most local abattoir. The meat returns to me, and I sell it through direct sales – farmers markets and such.

I also milk a herd of Jersey Cows for a fellow farmer; this is my happy place as I can just get on with the task and have space to think.

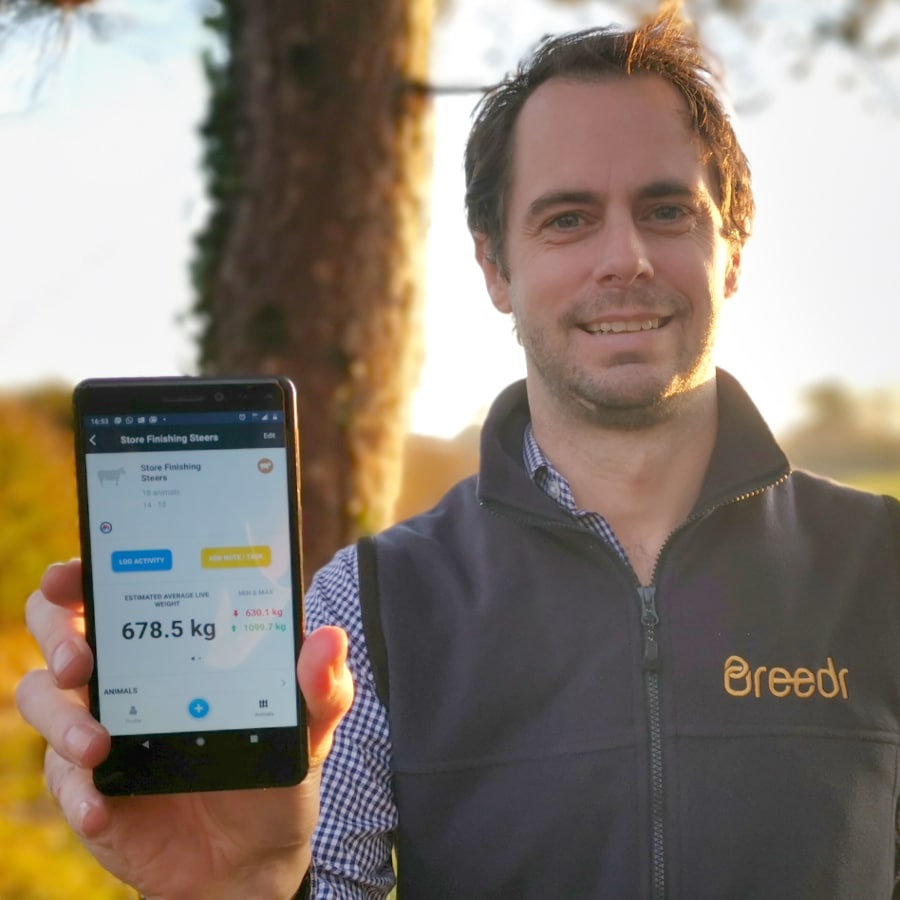

Livestock tech provides extra eyes for farmer

Although there is now a lot of technology available on-farm, I still use my stock person skills in order to maintain the health and welfare of the animals. Using the technology alongside my skills helps me to do that in a much better way. If you have 200 cows, you can’t be looking at each of them all of the time.

The cows are milked in a herringbone parlour with 24 machines. The cows are tempted into the parlour with a bit of food as a reward. They each have an electronic tag and as they come in this connects to computer system in the office just next door which detects and identifies the cow and records the milk yield from the milk meter.

Over-milking will damage the cow’s udder, causing infection and mastitis, which can be a really big thing. If you’ve got 12 cows lined up it can be hard to see which one has finished, so the milk meter is invaluable: it shows you the milk yield for each cow and also automatically disconnects the cluster from the udder when the cow has been milked out.

Heat time collar has been widely adopted

A recent development is the heat time collar, which acts as type of Fitbit for cattle and tells you information about their movement.

A cow is worth £1,500 to £2,000 and its offspring around £800 to £1,000 so getting the cow into calf at the right time is very important.

When a cow is coming into heat, that is the time you need to inseminate them for breeding. However, it is difficult to predict, and you might not be with them at the time.

The collar detects the cow becoming more restless, by monitoring the muscles around its tail and neck. This can be a sign it is coming into heat and sends this message to my phone.

The collar can also provide an early sign that the animal is unwell.

The first sign of the cow being poorly is that it will stop ruminating properly. Rumination is the process where a cow breaks down food within its digestive system, by chewing on its cud.

The collar can detect that within about 30 minutes to an hour. When this flashes up on my device, I know to immediately get in the car and see what is wrong.

Early attention can help to prevent loss of production, and at the end of the day if you don’t have the finances sorted, then nothing else matters.

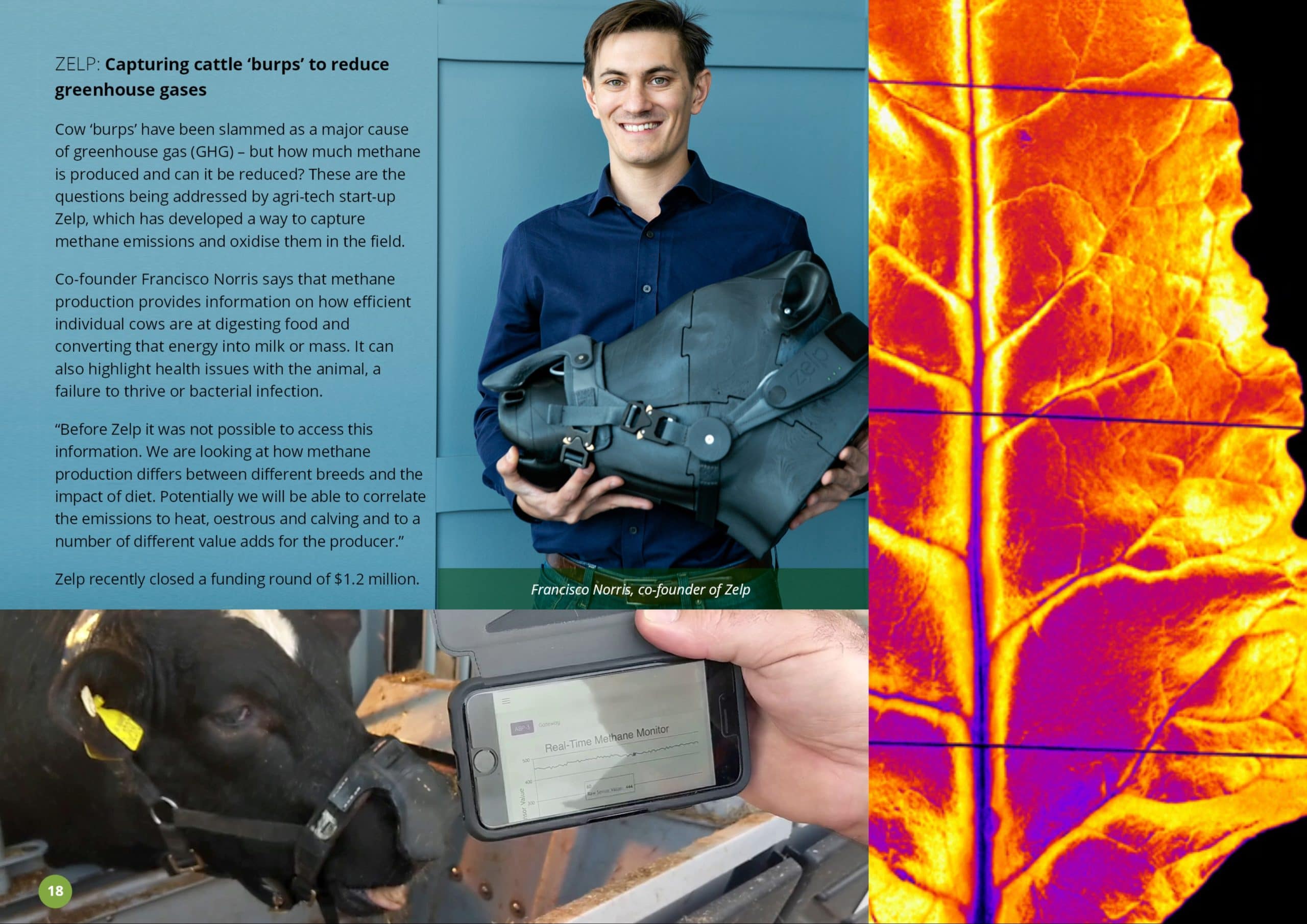

REAP provides an opportunity to see the latest technology developments – Zelp and HerdVision have featured in the Start-Up Showcase.

Future technology

REAP is a good place to hear about new developments.

Something I have been watching with interest is an alternative to electric fencing. The idea is that it offers more flexibility than fixed fencing and is safer than electric fences. As someone who has spent a lot of time with a strimmer underneath electric fence lines trying not to short it, the idea of an alternative is very appealing.

Virtual fencing systems offer a lot of benefits for increasing the productivity of pasture management.

The boundary is set by a map on your mobile phone and the cows wear a collar that alerts them when they are straying too far.

I’m not sure whether I would trust the technology straight away, but I might be tempted to trial it in a remote area.

As a farmer, you need to be innovative and always looking at ways to improve productivity. As a technologist I would stress the following key points.

Key points

- Technology must be accessible and fit in with the way that farmers work, as every farm is different.

- Technology won’t replace the skills of a stock person – but it will improve the way that they work.

- If technology improves productivity, it will be quickly adopted – nearly all the cows in our region now have the heat collars.

- REAP is a good place to see the science and the technology that is in development.

REAP is a good place to exchange ideas with people you wouldn’t normally meet out on the farm, and I am looking forward to joining the Farmer Panel this year.

Agri-TechE

Agri-TechE