Is agriculture the oldest – and newest – form of manufacturing?

This month we’ve been thinking about manufacturing, what it means, how it applies to agriculture and why it even matters.

Traditionally the word “manufacturing” conjures up images of landscapes dominated by resource-hungry heavy industry, quite at odds with the vision of a nature-based production system of plants and animals.

But looking back – and forward – reveals they might be closer than we might imagine.

What is manufacturing?

Manufacturing can be broadly defined as the conversion of raw materials into a finished product through the use of tools, machines, labour and chemical or biological processing.

So, what is photosynthesis, milk, meat or fleece production, if not manufacturing?

Following up from our recent event at the Manufacturing Technology Centre (MTC), and having just read the excellent book by Prof Tim Minshall (Head of the Institute of Manufacturing, University of Cambridge) “Your Life Is Manufactured: How We Make Things, Why It Matters and How We Can Do It Better” – we’ve been thinking more about what we can learn from the principles of manufacturing, and how to apply them to agriculture – as Tim Minshall says – to “do it better.”

Does Nature operate a “design-build-test” cycle?

Arguably, yes. Although unlike targeted product design, evolution doesn’t aim for a specific end goal– random genetic changes happen that impact a lot of individuals, and by chance, some of those changes leave their offspring better suited to survive and thrive in their environment.

But the incremental improvements brought about by evolution operate along the same principles as a rational “design-test-build” approach.

Taking the analogy even further, plant breeding (particularly with the new tools for precision breeding) enables faster and more targeted “evolution” of crops and livestock, designed to a specific end, such as increased yield or better stress tolerance.

Mass, batch or custom-made?

The three main approaches to how most things are made are mass production (a large quantity of standardised products is made), in batches (for limited, higher value products) or custom-made – where the product is unique or specialised.

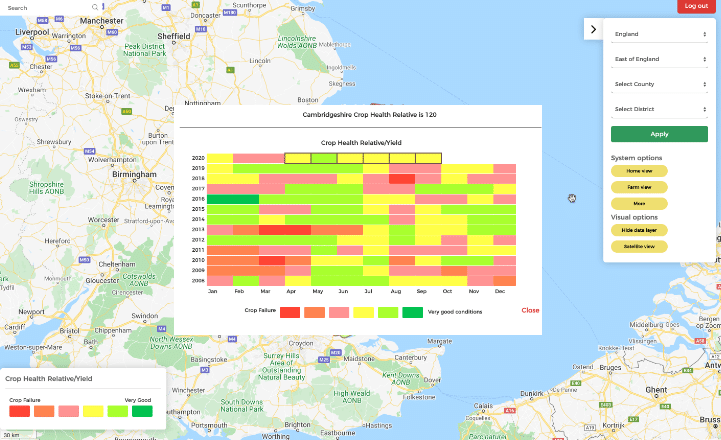

Again, we can see the parallels with agriculture. Arguably, commodity crops are mass produced (around 800 million tonnes of wheat globally last year, for example), while higher value crops such as salads and glasshouse plants are batch produced, while vertical farming and controlled environment production paves the way for high value crops such as those producing pharmaceuticals or other valuable proteins, for example.

Doing it better

Tim Minshall advocates for more sustainable and responsible manufacturing practices, harnessing circular economies, better supply chain transparency, and a focus on innovation to minimise waste and improve the environmental and social impact of production.

Sound familiar to conversations around agriculture and horticulture? Our recent event at the MTC discussing this very topic predictably positioned automation and robotics as key to this transition, but we realised it is more than technology – it is a collaborative mindset and a manufacturing-based approach that could be needed.

Why does it matter?

The current global geopolitical uncertainty, and trade tariff turmoil are starting to place a sharper focus on the manufacturing capability of countries and their potential for growth. The ability to generate higher value goods and products is increasingly seen as being a core capability.

So, recognising manufacturing principles and applying them to agriculture has many benefits. It changes mindsets and enables more efficient and sustainable processes – being “leaner” (to use another manufacturing term).

And recognition of the production of food and ecosystem services as bring the valued outputs of am efficient, high-value manufacturing capability can only be a good thing politically in these turbulent times.

Agri-TechE

Agri-TechE