GrowPura increasing the productivity and profitability of vertical farming

GrowPura Limited has developed the world’s first automated, moving conveyor system for vertical farming that operates in a patented ‘Clean Room’ environment. The company will be discussing the benefits of the system in the 2023 Innovation Hub at the Royal Norfolk Show.

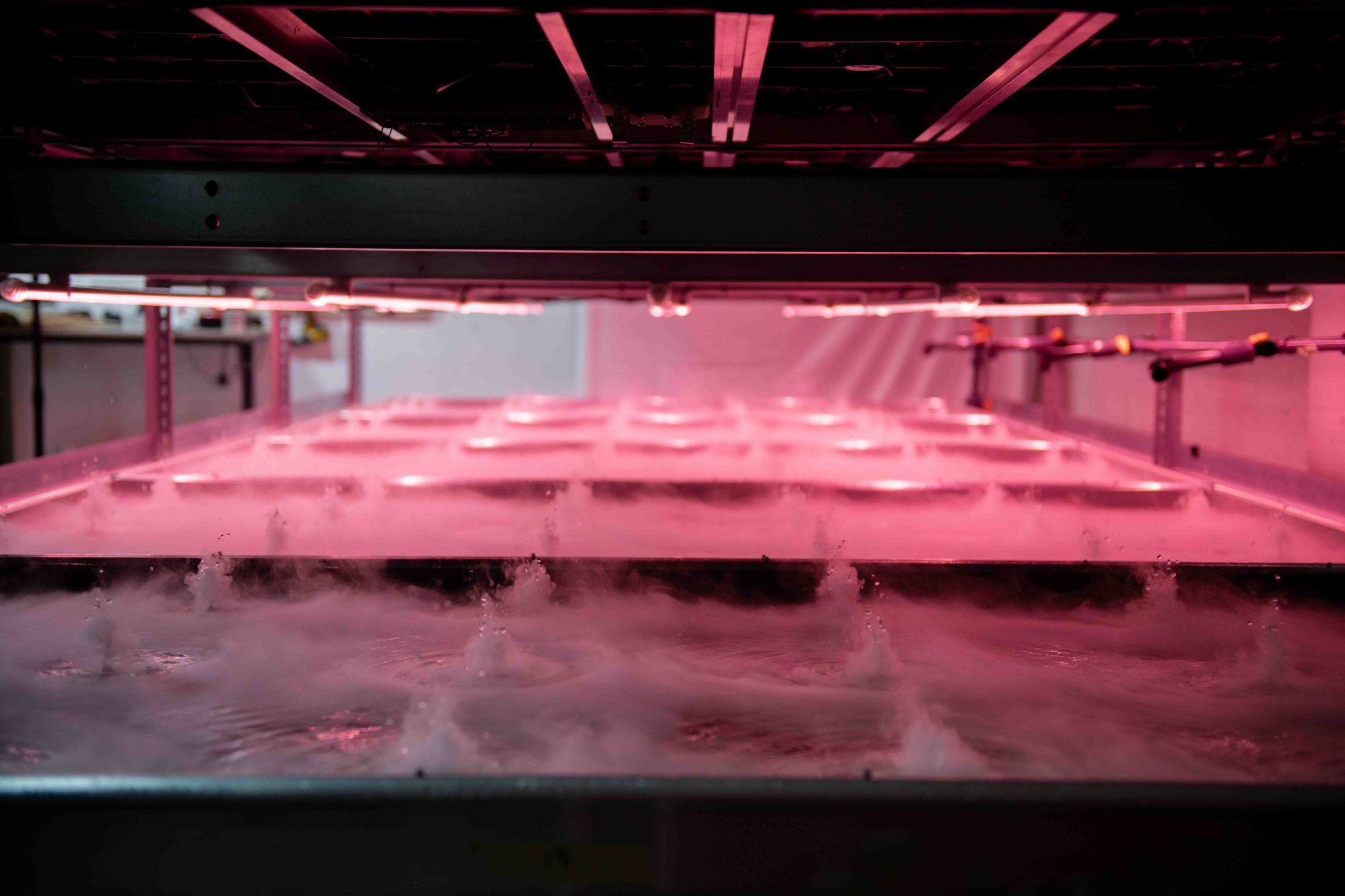

The GrowPura® technology maximises the use of space and reduces input costs. Plants are grown in a vertical hydroponic system with multilevel stacked trays. These move within a bio-hall and are continuously monitored to ensure each tray receives optimum light for growth.

Reducing inputs

As 95% of the water used is recycled it uses a fraction of the water required for field irrigated crops with no runoff.

All aspects of the environment – atmosphere, irrigation, level of lighting, humidity and temperature – can be calibrated to the crop to maximise production efficiency.

The system also uses less energy than conventional vertical farming systems. For example, it uses 50% less LED lighting and requires 50-75% less space. This results in significantly higher output compared to static hydroponic vertical farming methods.

Clean Room environment

All operations – propagation, growing and packing – take place within the clean room environment which uses filtered air and integrated barrier controls to remove the need for pesticides or washing. This means that crops have a longer shelf life once harvested.

The GrowPura® technology improves the economics and reduces the environmental impact of vertical farming while improving the quality of food produced.

The patented technology is available for licensing and turnkey solutions for vertical farming companies.

GrowPura is appearing in the Innovation Hub at the 2023 Royal Norfolk Show.

Read more about the 2023 Innovation Hub >>

Agri-TechE

Agri-TechE