Could open innovation across the supply chain unlock agri-tech of the future?

Market forces are changing companies’ approach to innovation throughout the ag supply chain. We look at the vital role collaboration and open innovation play in the development and adoption of new technologies.

Extreme weather, stricter regulations, and a drive for sustainability mean farming is returning to system-based solutions rather than singular inputs, which is typified by the rise of regenerative agriculture.

The interconnectivity of farming systems drives even the biggest ag businesses to look further than their capabilities to deliver future innovations.

This approach is known as open innovation. It is built on the premise that organisations can create a bigger pool of ideas and solutions by connecting internal and external knowledge. In an agricultural context, this often means collaborations between large ag companies, smaller firms or start-ups, research organisations and farmer groups.

Unilever has been using open innovation to develop nutritious, sustainable, and fair food, says James Holmes plant science and technology lead for Unilever.

“Unilever’s mantra is that ‘if we think we can do it alone, we are not thinking big enough’. The diversity of crops, production systems and geographical spread requires an open and collaborative approach to developing and implementing innovation with expert and local partners,” says James.

Phil Taylor, director of ecosystem development for Crop Science R&D at Bayer, sees integrated value chains as the future. He argues that the days of simply selling seeds, traits and synthetic chemistry are long gone.

“The world of agriculture has become more complex, and there is greater need for cooperation, decision support and targeted interventions.

“If industry doesn’t have a value proposition for the farmer, then it is not going to happen. We can have all the tools and technologies, but if at the end of the day it doesn’t fit the farming business model it’s being plugged into, it’s not going anywhere.

“As an industry, we have spent the last five years recognising that we need to work together, and the next ten years will be about how to make the whole system sustainable and self-supporting. To achieve this, we need to find new ways of partnering.”

Machinery is a crucial supply chain integrator, and the consolidated market means a handful of companies facilitate access to many of the agri-tech solutions in development by smaller firms. Mark James, John Deere sprayer product sales specialist, sees their role as ensuring equipment is compatible with as many different systems as possible.

Mark cites the development of closed transfer systems as an excellent example. Several competing closed transfer systems were available, all pushing for their design to become the industry standard.

“The one thing we don’t want to do in this situation is create something that is proprietary. It limits our customer’s choices and pushes them down a closed route.

We want to be as open to as many people as possible.

We got involved in collaborating with other industry members to formulate the ISO standard for the coupling connection.”

End-to-end collaboration

Colman’s is an iconic Unilever brand that produces English mustard and mint sauce, among other products. It has a long and illustrious history going back to 1814, and some farming families have been growing mustard for Colman’s for five generations.

With such strong farmer links to Colman’s, James saw an opportunity to utilise the open innovation approach.

“It takes around 4 million hectares of land to grow the crops Unilever uses to create its products, and since 2020, we have been supporting groups of farmers to adopt regenerative farming practices,” explains James.

“Unilever has been supporting farmers through open innovation to identify, develop and ultimately scale implementation of the innovative practices and technology required to reduce greenhouse gas emissions and limit global warming.”

Like all crops, mustard needs nitrogen fertiliser to reach its target yield. However, the application of ammonium nitrate or urea remains a significant proportion of the carbon footprint associated with mustard and mint crops, says James.

Unilever, Niab, growers and their existing agronomy partner Hutchinsons collectively agreed on a series of trials of regenerative farming practices, including reducing reliance on artificial fertiliser, testing irrigation technology, reducing cultivation and developing conservation biocontrol methods.

“Working with Niab has enabled us to set up a number of trials, testing practices and technologies on commercial farms.

“With Hutchisons’ experience, we were able to identify a number with the potential to reduce the crop requirement for artificial nitrogen. These were put through their paces on farms last spring and will be trialled for a second time in spring 2025,” adds James.

Regen is the catalyst for novel collaboration

Traditionally, Bayer has been seen by early-stage companies and academic entrepreneurs as a potential customer for a trade sale or acquisition of intellectual property (IP). The emergence of biologicals, active ingredients based on naturally occurring products, has changed that dynamic.

Phil Taylor explains Bayer’s fresh approach to collaborative innovation.

“Until recently, major innovations in traits or chemistry coming to the market needed a very heavy lift from a regulatory or product development perspective, and only the big guys had the firepower to deliver.

“Now the innovation landscape in agriculture is so much broader, with much more opportunity for smaller companies to contribute and stay part of the bigger story.

“With biologicals, we saw a mass of start-ups coming through with novel collections, screening capabilities and such, so the decision was made to lean into our strengths in development and integration.

“The result is we now take a licensing and partnership approach to the early research and let the experts drive it. We can come in with our leadership in product development and regulation and help get it out the door.”

Compatibility is key

Many crop monitoring and decision-support systems rely on fertiliser spreaders and spray technology to deliver variable-rate applications. Like with closed transfer systems, Mark James says John Deere has collaborated to develop a standard file format to upload data to its sprayers from any origin.

John Deere also goes to extremes to ensure its machines are ISOBUS compatible so that anything from another manufacturer can be plugged into a John Deere tractor, and it works.

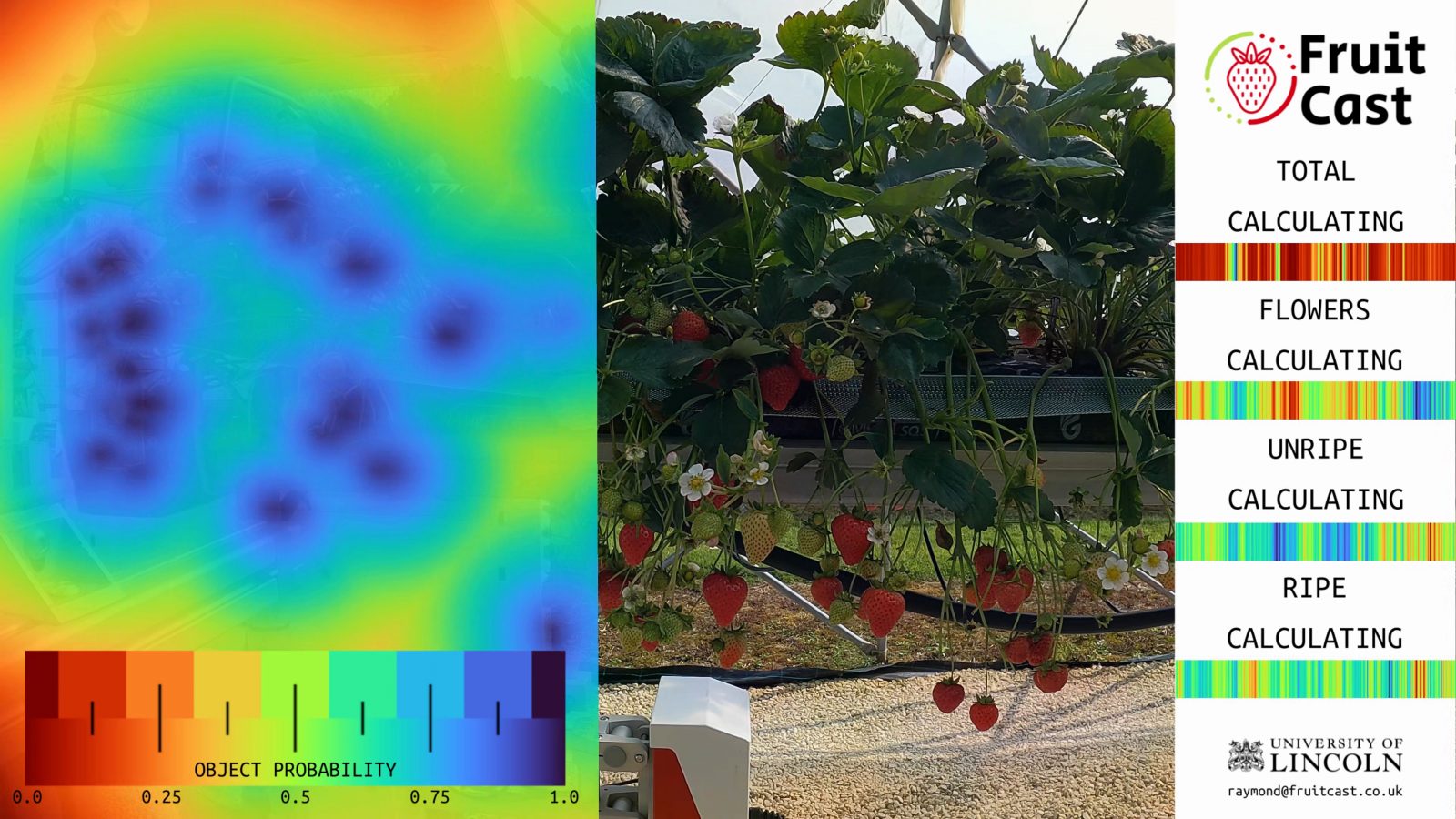

This open approach is more complex with cutting-edge technology, where one manufacturer may lead the rest of the industry. Mark notes John Deere’s See & Spray as an example of this. It is a camera-based spraying technology that uses machine learning and advanced cameras to spray weeds in crops selectively.

“There are cameras mounted every metre on a 36m spray boom. They spot the weeds in the fields with varying degrees of resolution, whether it’s identifying the shape of the weed or just the green area.

“To do that, the amount of data moving through the system is way more than the industry standard technologies can handle. When it’s operating, it moves something like 5GB of data down a spray boom, which is massive.

“It is here where we need to do something exclusive to the system. Hopefully, that will become the basis for the following standard and be incorporated into subsequent versions to be compatible again,” finishes Mark.

The Supply Chain Panel at REAP 2024

Phil Taylor, James Holmes and Mark James make up the effective and sustainable supply chain panel at REAP 2024, chaired by Calum Murray, Head of Agriculture and Food at Innovate UK.

They hope to explore open innovation further and how smaller companies connect and interact with larger firms at different points. The session will also recognise how farmers aren’t always the end users of tech and organisations across the supply chain utilise and enable it at different points.

To see and interact with the panel first-hand, book a ticket for REAP 2024 – on 6th November, Newmarket Racecourse.

Agri-TechE

Agri-TechE