Growers could save thousands each year with Albotherm’s heat-sensitive coating

A heat sensitive coating, which optimises the amount of sunlight entering the greenhouse or polytunnel, could save growers thousands of pounds each year by removing the annual cost of applying and removing shade paints.

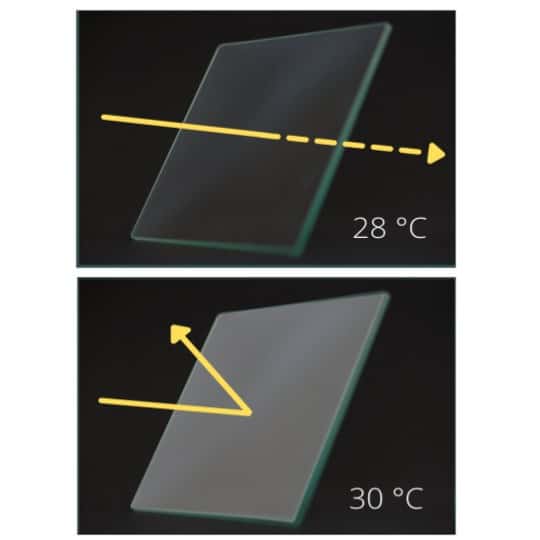

The coating, developed by University of Bristol spin-out Albotherm, stays transparent on cooler days to let maximum light through, but becomes opaque as temperatures rise.

Albotherm, presented in the REAP 2021 Start-Up Showcase.

Responsive coating moderates temperature

Molly Allington, CEO and Co-founder of Albotherm, explains that temperature control in the glasshouses is critical for maintaining crop health and maximising yields.

“In the UK, temperature control is achieved through application of shader paints, which act as a sun-protecting screen during the summer months and are then removed for the winter.

“Our coating would be applied once as a transparent layer. As the glass reaches a specific temperature it would gradually become opaque, and then become clear again as it cools. The benefit is that it would allow passive temperature control throughout the year and not require the costly painting and removal.”

The idea for the coating emerged during CTO Sian Fussell’s PhD research into temperature responsive materials, explains Molly: “Sian realised the materials could have applications in agriculture, so we built a bench-top model greenhouse in the lab and applied our materials. It worked really well, lowering the temperature by 5-10 degrees. That’s when we realised it could have real-world use.

“We are designing the thermoregulation product to be applied to the glass as a spray-painted coating, in the same way that current shade paints are applied, so it will fit within normal procedures.

Spray coating is time saving

Molly continues: “We are designing the thermoregulation product to be applied to the glass as a spray-painted coating, in the same way that current shade paints are applied, so it will fit within normal procedures.

“In the long term, we see this as a platform technology as we can use turn out materials into a coating for a range of materials, potentially including polytunnels. We are also able to create formulations that transition at different temperatures, ranging from 18 to 45 degrees, so we can control the amount of light that is being blocked, thereby cost-effectively maintaining optimum temperature and light level in the tunnel or glasshouse for different varieties of plants and climates

“Additionally, our technology can be used on conservatory roofs.”

The company is based at Future Space, an accelerator in Bristol, and is involved in product trials.

“Right now, we are refining the product for market – we’re pretty close to having a minimum viable product,” says Molly. “Moving forward, it’s a matter of improving the durability of that, and then scaling up over the next six months.”

Technologies to extract greater value from available light and the feasibility of year around production of green vegetables are among the topics to be discussed at the Agri-TechE event ‘Let there be Light’ hosted by the University of Essex Plant Innovation Centre on the 22nd February.

Find out more and book your place here.

Agri-TechE

Agri-TechE