ATW 2025: How can Agriculture Decarbonise the Supply Chain?

Agri-TechE Week 2025 celebrates its 12th year! Our largest yet, featuring 11 events curated by Agri-TechE and hosted by our incredible member community, followed by the REAP Conference on 4th November. This week exemplifies innovation, collaboration, and forward-thinking in agri-tech.

Each event reflects the strength of our ecosystem, showcasing what our community can achieve and bringing together our growers, researchers, and technology developers. A big thank you to our members for hosting – we wouldn’t have an agri-tech week without you and we are very proud to have your membership.

With Government and UK industries across the board looking at ways to decarbonise their operations, Niab asked the question; how can agriculture achieve this aim and contribute to sustainable revenue further down the supply chain?

Farmers are addressing multiple questions to achieve this but fundamentally, they want to produce good quality saleable crops, free from disease and pests, using all necessary inputs efficiently – and whilst maintaining their resources such as soil quality and ecosystem services. Industry-users need reliable, high-quality produce to survive in competitive markets, often dominated by high carbon, high energy-reliant systems.

Dr Lydia Smith welcomed all to Niab she noted that the event was not so well supported by farmers as in previous years of Agri-tech week, who are reeling from one of the worst harvests for 40 years, but making use of today’s fine weather.

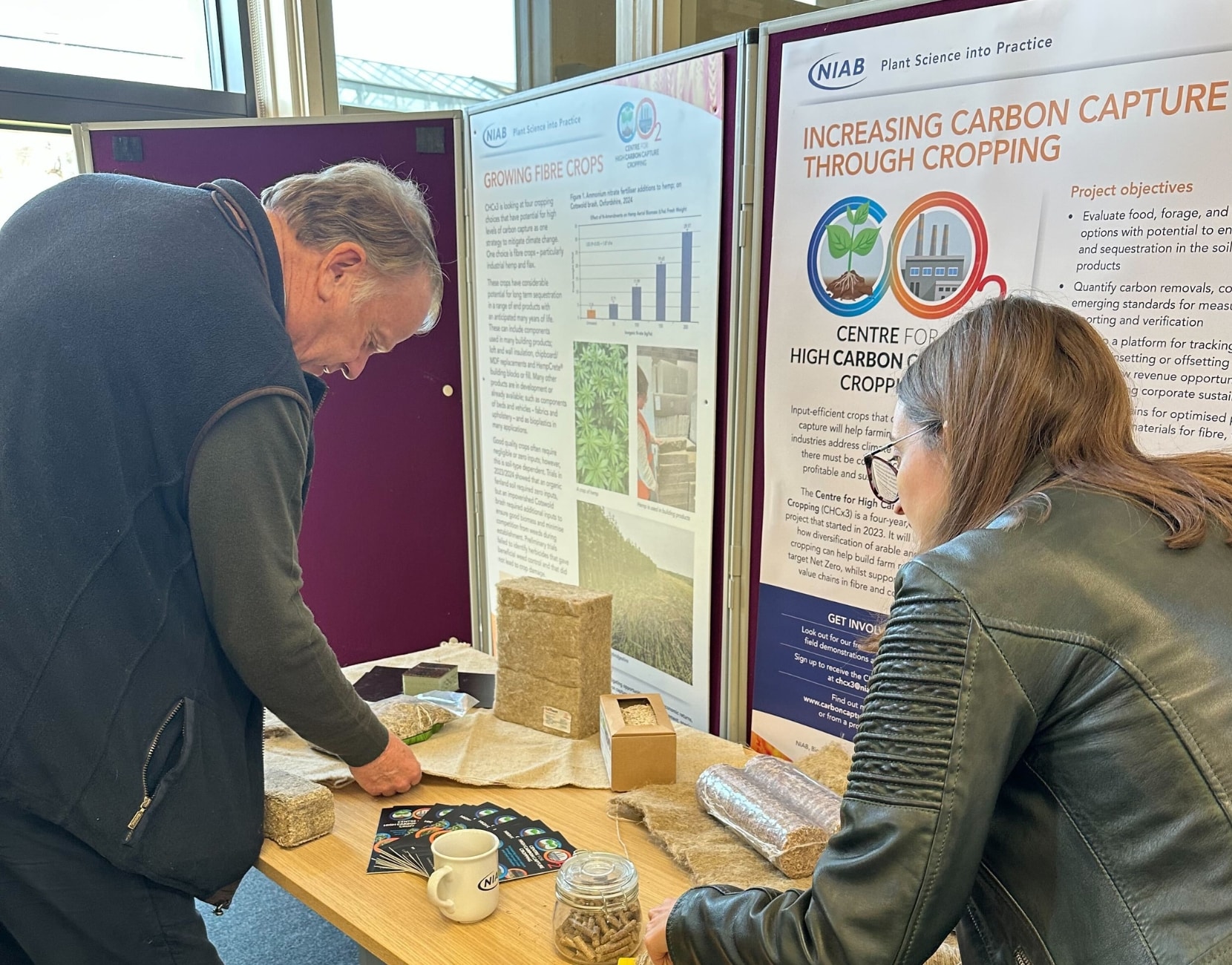

Lydia introduced the day through reference to The Centre for High Carbon Capture Cropping (CHCx3). This project, led by Niab, is targeting routes to carbon-capture and Net Zero through cropping and market development. Four exemplar crop groups are being considered along with their product outcomes and markets.

Using industrial hemp as an example, she referenced the routes to production of this crop, which are acceptable to users and does not present insuperable challenges in post-farmgate processing. The project is working with many stakeholders to provide resources, information and other help via the Hub.

Charlie Sampson, Finance Officer and CEO for Fibra described how his company is working ‘From Field to Factory – Decarbonising the UK Supply Chain with Hemp.

Fibra set out to address the lack of post farm-gate processing needed for industrial hemp fibre and shivs.

Fibra have set up a full turnkey solution to help farmers through all the potential pitfalls; enabling production of proven high-performance fibre and shiv for users across multiple sectors, from female hygiene products through to automotive parts. A real spring-break alternative to unpredictable peas, beans and rape, hemp provides a high C-Capture alternative with good gross margin and low input needs.

Florian Ilias, Managing Director from Terravesta is bringing Miscanthus to the forefront in Europe, a biomass crop with multiple applications, real potential for cultivation on less productive land and zero fertiliser requirement.

Like Fibra, Terravesta has set up full logistical support for farmers including planting, cutting and harvest infra-structure.

Miscanthus has suffered negative press for replacing food, but he notes that nearly 50% of maize, soybean and sugarcane are used for bioenergy. Furthermore, Miscanthus’ cropping lifecycle means that vital nutrients are returned to the soil before harvest. The combined extensive root biomass plus senescent leaves have huge soil-improvement capability. He notes that the UK is waking up to its merits and we are seeing rising demand, which will likely outstrip production if growers are slow to respond.

David Prior-Hope CTO from FIBE are developing technology to ‘Make Mass-Market sustainable Textile fibres from Agri-waste.

This relatively young company has, he says now developed innovative technology to produce high-quality yarn from waste potato haulms (stem). Since the fashion industry has the dubious record of being the “second-worst polluter after oil and gas”, he points out that this is a real, sensible and much needed alternative to both synthetic fabrics and cotton.

Potato haulme is a good choice; being a waste product from a major crop, but lacking applications in animal feed or AD, due to its toxin content, 4.6M tonnes/year is burnt; with huge contribution to CO2 emissions. A recent addition of hemp to their feedstocks is also looking very attractive to industry partners.

Chloe Donovan MD from Natural Building Systems introduced the audience to the concept of AGRITECTURE – utilisation of natural products for utilisation in buildings.

Like fashion, the building industry has an excessively high carbon footprint and is beginning to benefit from utilisation of natural locally sourced regenerative materials in house-building. A major feedstock for her innovations is industrial hemp, which is “equally efficient at capturing carbon as established forest’ and grows much more quickly to reach harvest – after only 100 days.

Their trademarked product HempSil® “improves air quality, has thermal and acoustic buffering reduces the risk of damp and mould and reduces the need for mechanical ventilation. Furthermore their ADEPT® production model introduces the concept of scalable manufacturing and for actually re-using or recycling components of buildings.

Farmer, Richard Bowe, has diversified his farming operations to set up a company that is producing products based on biochar.

His young company Re-Generation Earth is using the “ancient art of pyrolysis to produce biochar”; process the outcomes and mix with other ingredients such as chicken manure and utilising the heat from the production process for local heating solutions.

His feedstocks are primarily waste and material from hardwood forest maintenance, such as local horse chestnuts in Kent. Optimisation has benefited from interaction with the University of Kent under the Growing Kent and Medway support scheme. Ongoing work will utilise the fast growing Paulownia as a feedstock.

Dr Robert Jackson, Niab has been exploring the need for decarbonising agriculture from the viewpoint of highly efficient use of inputs that are used in agriculture and horticulture.

He has focussed on ‘Precision Orchard Management for (the) Environment – or the POME project led by Hutchinsons. This multi-partner collaboration is combining AI and remote sensing using DRONE technology to address use of crop husbandry in orchards.

Orchards have been a very high input system for years, due to the apparent customer need for perfect fruit allied to the many pests and diseases that can compromise this aim. The POME group has learnt to re-visualise an orchard so that developing blossom/fruit (and tree health) are identified. The outcome is highly focussed pruning and other treatments and a quantified reduction in expensive and high-carbon footprint management requirements.

Discussions in two rotating groups then discussed two vital components contributing to farmers-industry engaging on cultivation and use of novel and under-utilised crops feeding into the sort of value chains discussed in this event. The questions and delegate views are summarised below:

How can government incentivise farmers/growers to grow these sustainable product crops?

- Government would benefit from a better understanding of how Agriculture works; this could lead to incentives and help for end users – such as the incentives seen for industry to use sustainable biobased materials and systems seen in France, Germany and Netherlands.

- There are communication barriers; investment in infrastructure and knowledge – bases would facilitate better interaction between users and farmer-producers.

- Gov could contribute to establishing a more effective/fair carbon – market where there is shared responsibility AND benefit right along the supply chain

- Tax policy and legislation should be reviewed to both ensure a level – playing field for existing high-carbon products and novel biobased ones – alongside requirements for high energy-consumption/C-footprint industry to use a minimum level of sustainable products.

- UK regulation on imports to ensure that the whole value chain is sustainable end-to -end in comparison to UK produced sustainable alternatives

- Government provision of shared infrastructure to enable small and larger companies to process end-products; which can be rented by users to pay for themselves.

- Match funding or help from initiatives by big farmer organisations e.g. ‘Anglia Farmers in providing impetus and help to growers.

- Government could use templates from other industry to set up help or user ‘Hub’s such as is seen in glass industries.

How can industry and government reduce impediments to supply chains & end users to increase take-up?

- Delegates noted that Scotland now has a ‘Zero Waste Policy; England and Wales would benefit from similar legislation to help remove cost barriers to take up of valorised products

- Remove negative legislation that prevents use of novel or valorised or biobased products due to excessive and expensive testing regimes inappropriate to product safety issues.

- Liberate the potential for utilisation of large capital pots, which could be used to invest in biobased and sustainable technologies – such as pension funds

- Revisit national policies or government advice that prevent banks or other investors from supporting crops that have been artificially labelled as ‘high risk’ – such as Industrial hemp, which is erroneously linked to pharmaceutical crop lines.

- Ensure fair, transparent and accurate labelling of products so that consumers can more accurately choose sustainable products in line with their expectations

- Raise the profile of the benefits of Bioeconomy so that both consumers and industry can make more accurate decisions about their choices and preferences

- Contribute focussed legislation to more accurate pricing of Carbon within carbon-trading marketplaces and include Agricultural outcomes in Low-Carbon Net-Zero calculations and reports.

- Build on the excellent ADOPT; Farming Innovation Pathway calls; perhaps with slightly longer projects and a simpler set of questions.

Niab

Niab